A glue laminated timber is an engineered wood product meaning it is made from wood but is machined and assembled to precise specifications to create a predictable dimensionally stable building material.

Characteristics of glued laminated timber.

The apa mark of quality.

In north america the material providing the laminations is termed laminating stock or lamstock.

Glued timber is a wood product which does not fulfil the laminated timber standards but is made by gluing two or more items of sawn goods together.

Many different species of lumber can be used to produce glued laminated timber.

Strength graded and ready finished glued timber.

Other common engineered wood products include plywood oriented strandboard osb and laminated veneer lumber lvl.

Glued laminated timber made of beech and hybrid beams made of beech spruce.

Glulam can also be produced in curved shapes offering extensive design flexibility.

Dry lumber and characteristics unique to the glued laminated timber manufactur ing process such as being able to vary the grade of lumber throughout the depth of the member.

Glulam beams manufactured by apa members are certified with the apa trademark.

Glued laminated timber also abbreviated glulam is a type of structural engineered wood product constituted by layers of dimensional lumber bonded together with durable moisture resistant structural adhesives.

In addition a wide range of grades of both visually graded and mechanically.

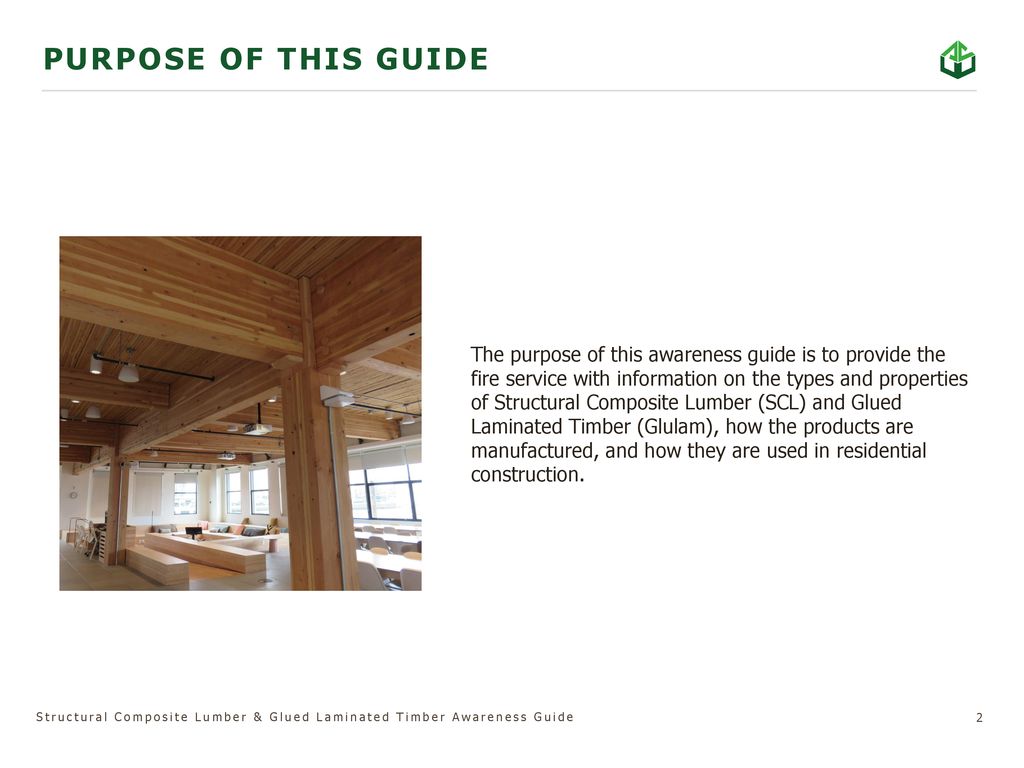

Glue laminated timber glulam is a structural engineered wood product commonly used for beams and columns in residential and commercial applications.

It is the basic material in manufacturing glued laminated timber.

Wood is one of the oldest construction materials.

It is a highly visible form of mass timber in contemporary projects with long spans framing signature designs left exposed to take advantage of wood s natural aesthetic.

Certification of the product an the producer.

Glued laminated timber glulam is composed of several layers of dimensional timber glued together with moisture resistant adhesives creating a large strong structural member that can be used as vertical columns or horizontal beams.

The functional properties of glulam structures are such that wood as a traditional material allows for new construction challenges and imposes itself as one of the construction materials of the future.

Such products are used as they are in loadbearing construction and as blanks for various wood products such as window frames laminated logs etc.

The aim of this work is to investigate and compare the physical and mechanical properties of clt manufactured using prf and pur adhesives.

Glulam timber according to din 1052.

Cross section structure of glulam.